How to Design a Rover Attachment

Rover attachments are a great way to extend the Rover’s capabilities with 3D printing. It’s a wonderful way to upgrade or customise your Rover to suit any project imaginable.

Existing Attachments:

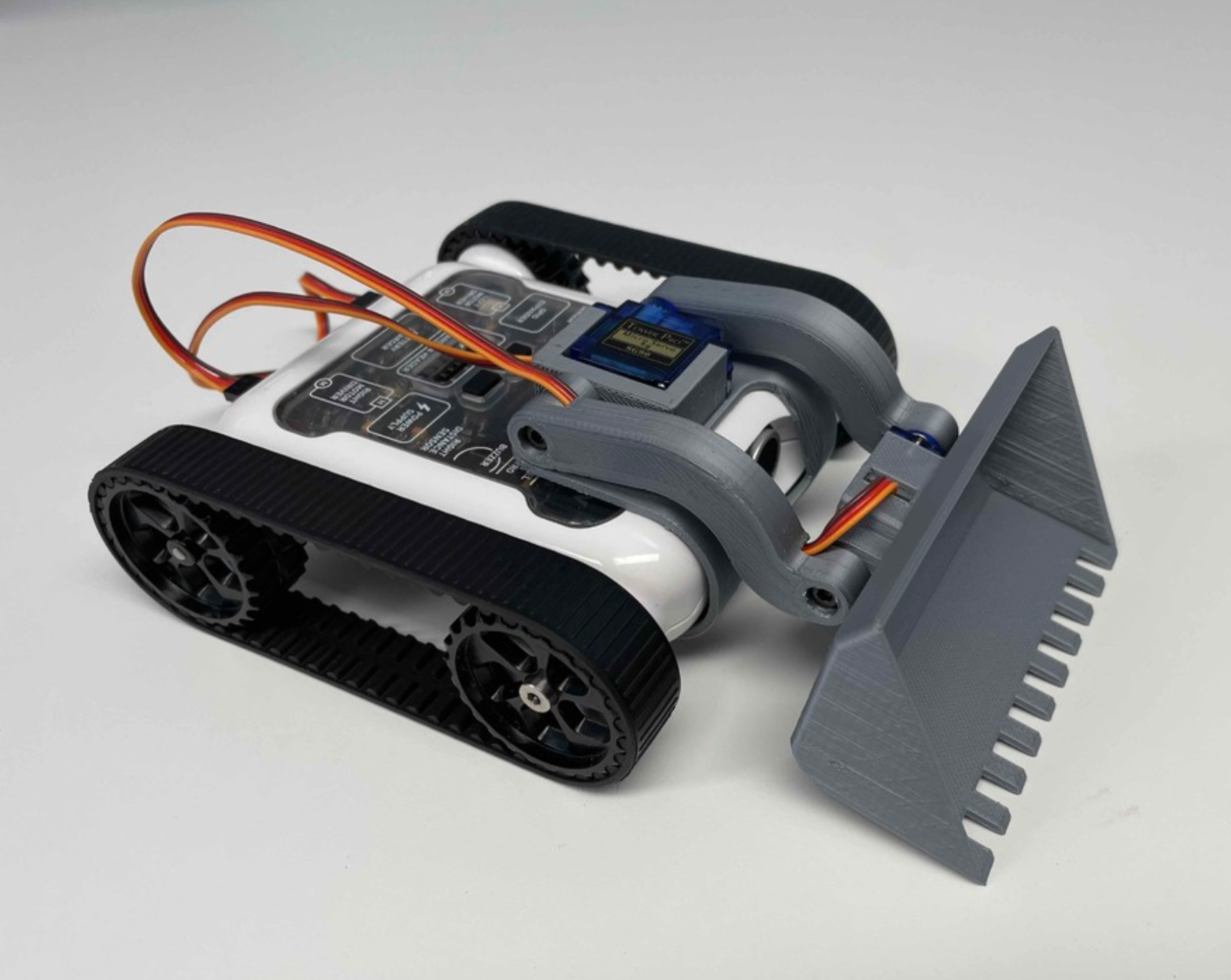

Here at Micromelon, we’ve already gone ahead and made a few attachments for you to use and take inspiration from. These attachments fit onto the mounting tabs on the rover body and utilise the sensors and servos to transform them into things such as diggers, tippers, or even add claws.

For further information about our existing attachments, visit our page on rover expansions.

Constraints:

It’s good to be aware of the constraints around what the rover can do before attempting to design the attachment.

Sensors:

For all your attachments, it’s helpful to use the existing sensors on the rover, like the ultrasonic sensor, for example. When using these sensors, the attachment must be made to not hinder their ability to operate (for example, ensuring the ultrasonic is not covered up). An attachment could be designed to hold an Arduino to serve as an expansion board for additional sensors.

Actuators and Power:

The rover has two servo ports at the back. This means you are limited to only using a maximum of two servos without further modifications. Additionally, there is a limit to the power the rover can output. When using a servo expander with I2C, the rover may find it difficult to power many actuators simultaneously. Also, the attachment must not be too heavy as the rover motors cannot handle a significant weight increase without a decrease in speed.

How to get started:

Before starting, it is a good idea to have some practice in 3D designing software such as Fusion 360, as some of these designs can get complex.

Step 1: The first step after considering a design is to allocate the servos. As discussed in the constraints, the limitation of servos means moving components on the attachment must be considered carefully.

Step 2: Next, download the basic rover shell from this link: Basic Shell

Step 3: Starting from the rover shell upwards, take the attachment step by step. Let's start with where the servos are going to sit. Then finish all your static components before going on the moving pieces. Think about how many parts you want your attachment to be made of. One part? Or an assembly of many parts?

Tips and tricks:

Component Sketches:

Below are some valuable sketches and components that can be used to design your attachment.

Connections:

When printing your design, breaking up the attachment into smaller, easy-to-print parts is recommended. This will ensure a robust, high-quality design that can be quickly prototyped. The connections between these parts must be considered when making a multi-part design. Refer to the 3D printing connections guide to determine which techniques suit your design.

Gears:

While the designs are limited to two servos, the output of these actuators can be modified to suit your needs. For example, the half-rotation range of a standard servo can be increased through gears. Furthermore, the rotational movement of a servo can be changed to linear by using a rack and pinion system. For more information on gears and motion, refer to our Guide to Gears.

For a more detailed guide to 3D printing connections and gears, visit the pages shown below.