How to Maintain a 3D Printer

Like any machine, 3D printers wear out after long periods of use and require maintenance. Printers should be consistently maintained to prevent degradation in print quality and to reduce damage to the printer itself. This guide will take you through some main focus points regarding caring for a 3D printer.

Note that this guide is focused on Creality FDM printers, however, the concepts are applicable to all FDM 3D printers.

Belts:

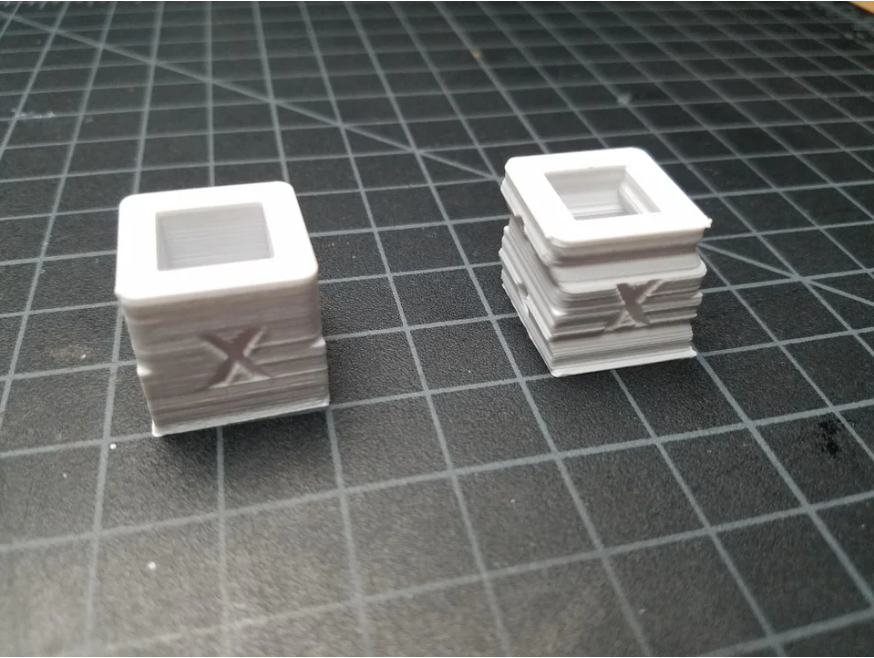

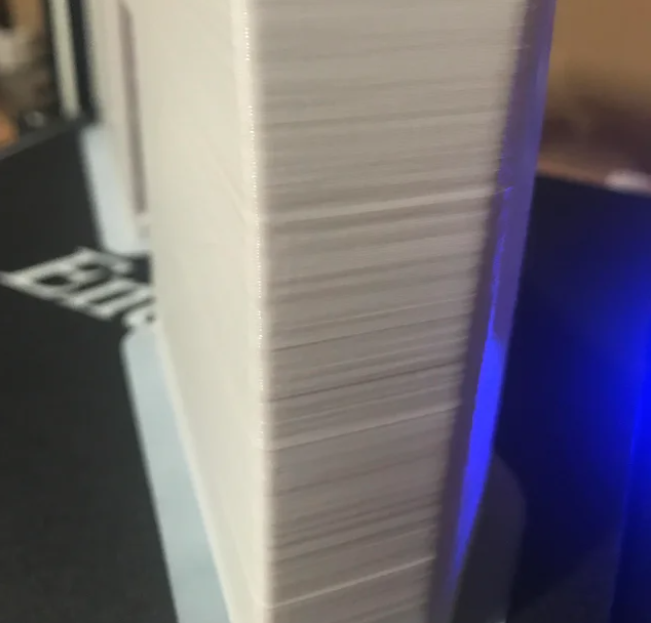

Belts are usually used on 3D printers to move two or more of the axes. Belts must always be kept well-tensioned, and neglecting to maintain belt tension may lead to several issues in print quality. These issues include deformed dimensions, print surface defects, and layer shifting.

Credit: pattertj (Reddit)

Credit: Fordari (Reddit)

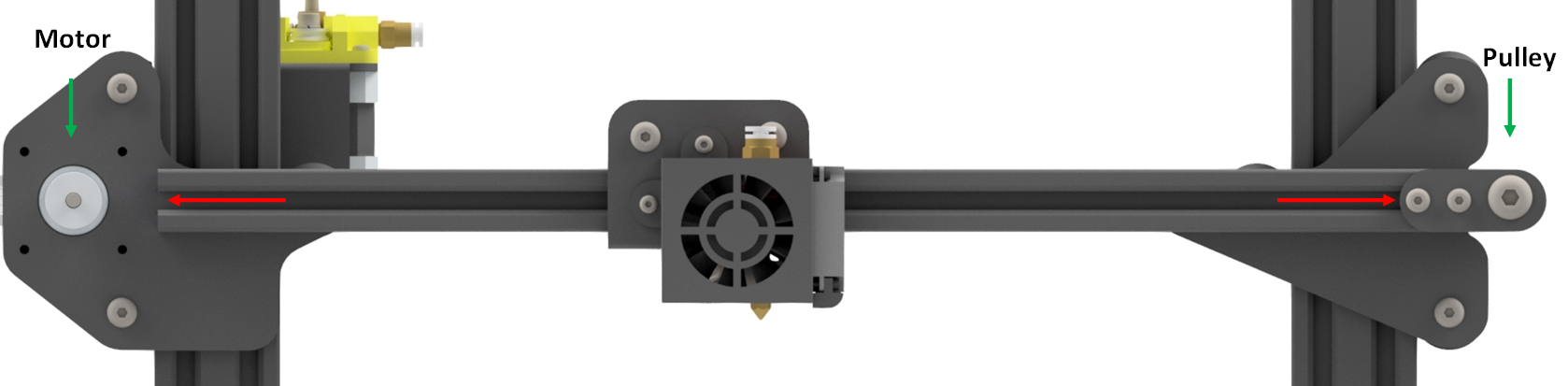

Generally, on FDM printers, each belt will have an end looped around a stepper motor and another looped around a free-running pulley. These systems will have their own way of tensioning a belt, usually a clamp on the belt or an adjustable pulley mount. To tension a belt on a printer, all that needs to be done is to increase the distance between the motor and the pulley, as seen by the red arrows in the image below. For example, on Ender 3D printers, the screws on the pulley mount can be loosened and pulled to the correct tension before tightening.

The belt needs to be tight enough so it doesn’t wobble when the axis moves but not so tight that it’s hard to move the axis.

Eccentric Nuts:

Any printer that uses V-slot extrusion slides (like the example above) will have eccentric nuts attached to the gantry. Again, this is a different type of tightening that can cause similar issues to loose belts. If the head of the printer or the build plate is wobbling, this may indicate the eccentric nuts need tightening.

The image above shows that an eccentric nut is just a hexagonal nut with an offset centre. Twisting this nut with a spanner (the gantry does not have to be disassembled for this) will reduce the distance between the wheels and give the gantry a tighter hold on the extrusion. Again make sure the nut is not so tight that it’s hard to move the gantry.

Levelling:

Many printers will, at some point, come across the issue of a print unsticking from the build plate. The frequency of this occurrence can be significantly reduced by correctly levelling the build plate. The idea is to get the nozzle to the perfect height from the build plate across the entire surface.

Credit: Raise3D

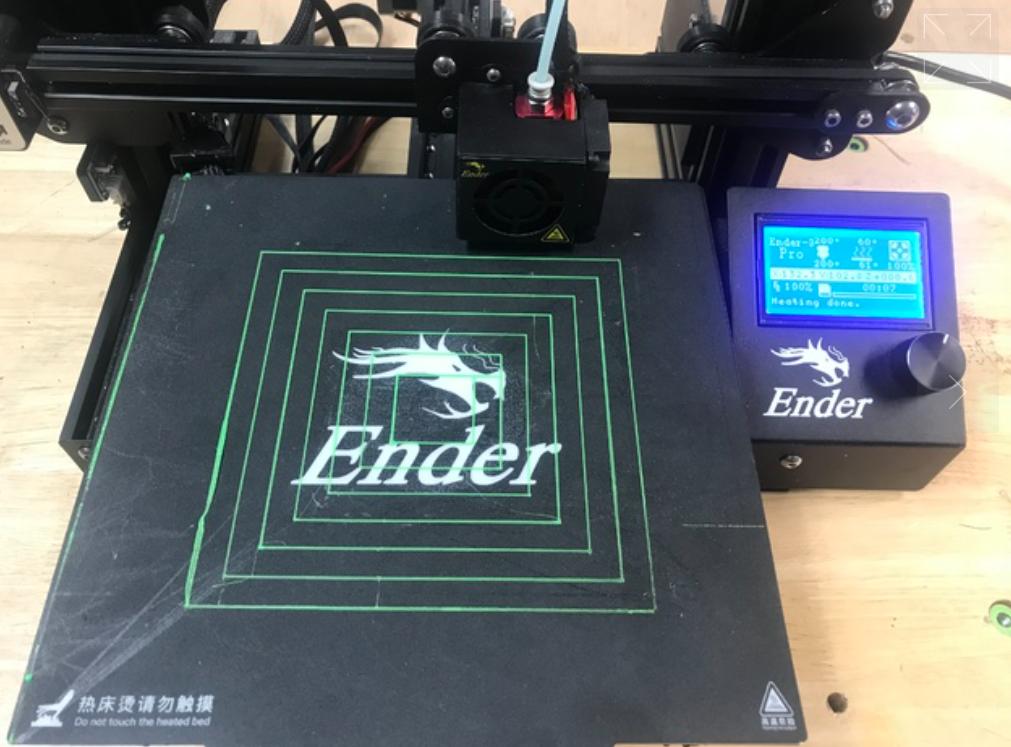

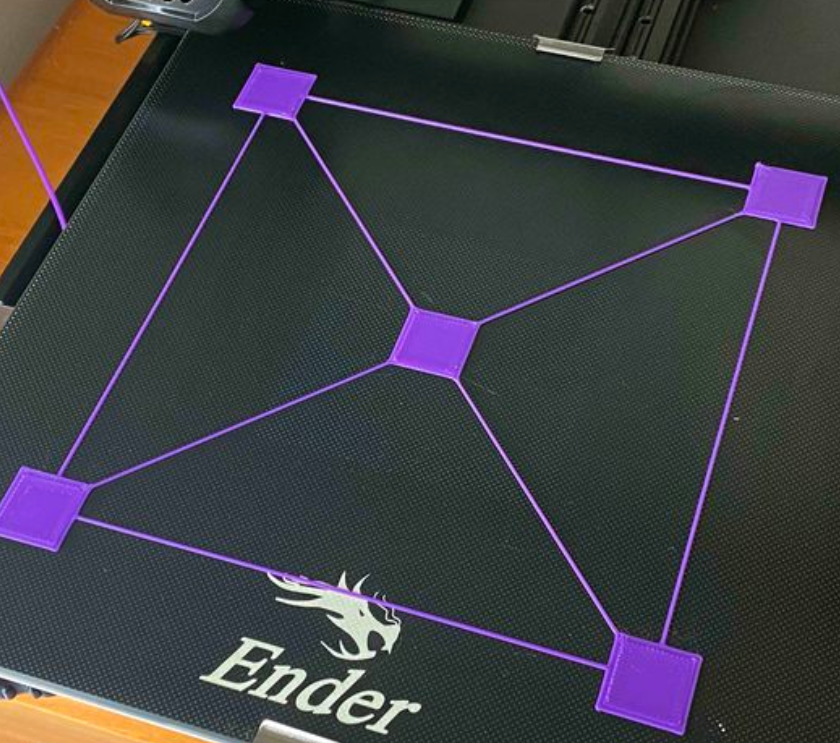

First, home the 3D printer, then disable the steppers (or turn the printer off). A great way to start levelling is to use a business card between the nozzle and the bed and tighten the nuts under the bed until you feel slight resistance when the card is moved. This process should be repeated twice. Then, an excellent way to properly fine-tune the levelling is to run a calibration print (some examples below).

Ender 3 Bed Level by Elproducts: Link to Files

Ender 3 Bed Level by sahansudeepa: Link to Files

Print these files (scale them for your printer) and compare the results with the image above from Raise3D. It’s helpful to make slight adjustments to the nuts on the bed during the print.

Nozzles:

Nozzles on 3D printers eventually wear out due to the constant flow of filament through them. The time this process takes may vary depending on which filaments are used. When a nozzle begins to wear out, you may experience the following issues:

Rough surfaces on prints.

Not enough filament extruding.

The nozzle becomes clogged.

The nozzle opening is too wide.

Once you have found the correct nozzle for your printer, the steps to change it out are pretty simple:

Credit: Prusa Research

Heat up the printer nozzle and remove the filament

Carefully unscrew the existing nozzle (it will be hot, so be careful). Hold the heat block with pliers or a spanner while you do this.

Screw in the new nozzle (while the printer is still hot). The nozzle must not be overtightened; it sometimes helps to tighten fully, then unscrew about a quarter-turn.

Finally, relevel the build plate.

Storing Filament:

While it may not seem that filament requires maintenance, proper measures must be taken to care for the rolls when not in use. This is because filament absorbs moisture and collects dust. This may significantly reduce the quality and strength of prints and cause the nozzle to clog more frequently.

A simple and effective way to store filament is to keep the rolls in an airtight container filled with reusable desiccant. For a more advanced system, it’s possible to construct a filament Dry-Box. There are many simple designs and guides out there, such as the article written by All3D: DIY Filament Dry Box: How to Build One on a Budget

Say Hi to Makerhero!

From filament, to repairs and spare parts. Micromelon has spent the last 6 years working with schools, businesses and individuals to repair, maintain and print great things. We run 3D printing training and webinars to the public focused around using 3D printers safely around students at schools, robotics clubs and at home.

We also own MakerHero, our very own 3D printing filament and parts brand.